Emission regulation often necessitates the need for flue gas treatment of acid gases within the utility and industrial sectors. In the US today, a number of important regulations including Utility MATS, Industrial Boiler MACT, Portland Cement MACT, regional haze rules, new source review (NSR), and site permits are direct drivers for the need to reduce acid gases such as HCl, SO2, SO3, and HF. Additionally, other promulgated and proposed rule-makings, such as the coal combustion residue rule and water rules such as the 316(b) rule for cooling tower intakes and the effluent limit guidelines (ELG) may also be significant and may lead to the need for flue gas treatment as a part of a comprehensive compliance strategy.

MATS

Whether you call it the utility Hazardous Air Pollutants (HAPS) rule, the utility MACT (Maximum Achievable Control Technology) rule or the Mercury Air Toxics Standards (MATS) rule, this rule developed for the power sector presents new challenges for coal fired utilities.

Fortunately, Dry Sorbent Injection (DSI) technology with Sorbacal® products has been proven to be capable of capturing enough HCl to achieve these new standards with all but the highest chloride fuels. DSI is a relatively easy to install, low capital cost compliance solution for many coal fired utilities.

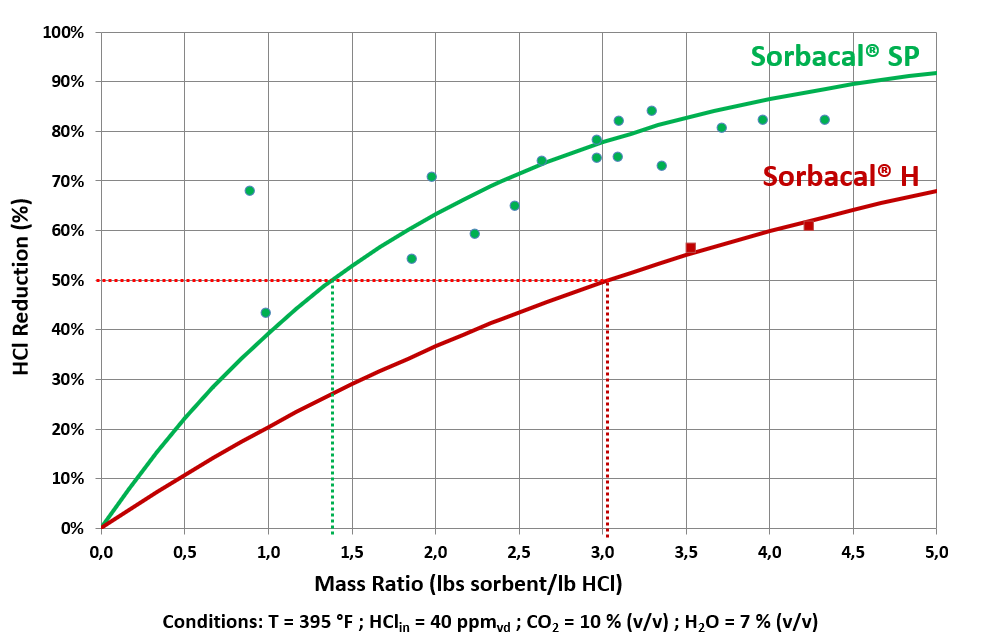

One example of MATS compliance within a utility is shown in the graph. In this case standard hydrate was not able to achieve the HCl emission limit outlined in MATS, while using Sorbacal® SP the limit could be achieved. In addition, at every level, the amount of reagent required when using Sorbacal® SP is much lower than with standard hydrated lime.

Sorbacal® DSI technology can also be utilized to capture SO3 and maximize native carbon mercury capture or to enhance capture with activated carbon (AC) injection systems.

for a reagent consumption estimate or to discuss a full scale field trial of Sorbacal® DSI technology.

Industrial Boiler MACT

The promulgated industrial boiler MACT (Maximum Achievable Control Technology) rule presents significant challenges for smaller coal or biomass fired boilers being used in industrial applications. The high capital costs associated with traditional acid gases control systems can put continued operations in jeopardy.

One example of testing at an industrial boiler to achieve MACT limits for HCl is shown below. In this case, Sorbacal® SP is shown to achieve the HCl emission limit outlined in IB MACT with half the amount of reagent when compared to standard hydrated lime.

Fortunately, Dry Sorbent Injection (DSI) technology with Sorbacal® products has been demonstrated to capture HCl on a wide variety of industrial boiler applications in order to meet the emission limits set forth in this rule. This is a relatively low capital cost compliance solution that can mean the difference between shutdown and being able to continue operations.

In addition, Sorbacal® DSI technology can be utilized to capture SO3 and maximize native carbon mercury capture or to enhance capture with activated carbon (AC) injection systems.

for a reagent consumption estimate or to discuss a full scale field trial of Sorbacal® DSI technology.

Regional Haze

With the second planning period of the Regional Haze Rule, the Environmental Protection Agency (EPA) is renewing its attention to additional considerations for improving visibility, specifically SO2 and NOx reductions, from a wide variety of utilities and industrial facilities combusting coal and/or biomass. Dry Sorbent Injection (DSI) technology with Sorbacal® products has been proven to be highly effective for SO2 capture and has become a preferred solution for utility and industrial applications.

In many cases controlling SO3, whether inherent in the existing process or compounded by NOx control technology retrofits, Dry Sorbent Injection technology can address this concern. Over the last 10 years, DSI technology with Sorbacal® products has been proven to be highly effective for SO3 capture and has become the preferred solution for utility and industrial applications. This technology is in use at literally dozens of coal fired plants today.

for a reagent consumption estimate or to discuss a full scale field trial of Sorbacal® DSI technology.

Portland Cement MACT

After years of legal wrangling, the Portland Cement MACT (Maximum Achievable Control Technology) rule has been finalized. This rule establishes a number of new emission limits, including HCl, for Portland Cement kiln operations. While the specific kiln type, fuels, raw materials and methods of operation come into play, many cement kiln operators will need to actively control hydrogen chloride emissions.

One example of testing at a U.S. cement plant is shown on the graph. In this case, the limit in the PC MACT for HCl can be achieved using hydrated lime, but the amount of Sorbacal® SP to achieve the same emission limit is significantly reduced.

For many kiln configurations, Dry Sorbent Injection (DSI) technology with Sorbacal® products has been proven to be a viable technology to meet the HCl limits associated with this rule with relatively low capital costs. Additional benefits related to SO2 capture have also been demonstrated.

for a reagent consumption estimate or to discuss a full scale field trial of Sorbacal® DSI technology.

Coal Combustion Residue (CCR) Rules

With the development of rules for management of CCR materials in 2014, the impacts of retrofitting emission control technology must be considered. This is especially true with Dry Sorbent Injection (DSI) technology. Both sodium and calcium based DSI reagents will impact the resulting CCR materials.

Whether bound for disposal or a reuse market, the impacts on the CCR metals leachability and solubility must be considered. In general, CCR materials impacted by the use of sodium DSI reagents leach higher levels of metals and result in dramatically higher potential for dissolved solids than the raw CCR or CCR impacted by calcium DSI reagents.

These impacts can be modeled and estimated for a given DSI application.

if interested in evaluating these important potential impacts on your CCR material.

Effluent Limitation Guidelines (ELG)

The development of the Effluent Limitation Guidelines (ELG) results in utilities seeking to minimize process heavy metal discharges (e.g. mercury, arsenic, selenium) and seeking to recirculate scrubber liquor to the maximum extent possible. The amount of recirculation is often limited by chloride concentration in the scrubber liquor. Sorbacal® hydrated lime is highly effective in controlling HCl emissions as well as removing vapor-phase selenium from the flue gas prior to entry into the wet scrubber. For example, reducing HCl by 50% at the wet scrubber inlet provides the ability to recycle scrubber liquor twice as much. While other treatment options are available for ELG, they are generally quite expensive.

An alternative approach being employed by some affected utilities is to simultaneously capture and remove both chlorides and selenium compounds in the gas steam, prior to entering the wet scrubber. Dry Sorbent Injection (DSI) with Sorbacal® makes it possible to capture chlorides and selenium from the flue gas, and remove the reaction products (i.e. calcium chloride and calcium selenite and selenate) with the fly ash (e.g. in the electrostatic precipitator or fabric filter). The resulting calcium reaction products formed can then be more economically handled in the solid state.

Minimizing the chlorides and selenium ultimately reporting to the scrubber, allows for higher recirculation of waters without expensive treatment alternatives.

to discuss the possibility of performing a full scale field trial using Sorbacal® DSI technology to remove chlorides prior to your wet scrubber system.

Sulfur Dioxide National Ambient Air Quality Standards (NAAQS)

In August 2015, the U.S. Environmental Protection Agency (EPA) issued the SO2 Data Requirements Rule (DRR), which directed air agencies to identify maximum ambient air 1-hour SO2 concentrations in areas with large sources of SO2 emissions. The purposes of the DRR was to identify SO2-emitting sources with annual emissions greater than 2000 tons and those sources that have not been previously captured as part of the initial SO2 National Ambient Air Quality Standards (NAAQS) non-attainment designations. Once agencies had identified large emitting sources, owners where mandated to determine if the area surrounding the source was in attainment with the SO2 NAAQS via modelling, monitoring or assuming enforceable permit conditions assuring compliance.

Advancements in calcium hydroxide DSI reagents, specifically Sorbacal® SPS, have resulted in products that can achieve high removal efficiencies for SO2 emissions with relatively low capital cost injection systems. Whether as “add-on” controls to existing FGD system or as a newly-install system for SO2 mitigation, DSI can achieve high SO2 removal efficiencies when using Sorbacal® SPS. The ultimate effectiveness will be a function of a wide variety of variables, including exhaust gas properties such as acid gas concentration, flue gas moisture content, available particulate collection devices and injection system configuration. For further information look here !